Blog

Are All ATP Luminometers Created Equal?

I have a question for you.

Do you feel like your ATP sanitation verification program is adding value to your product quality and sanitation procedure? If your answer is ‘we consistently get low relative light units (RLU), but we have elevated bacteria counts’ putting product on hold/consumer complaints, or ‘our RLU’s are low, but we have problems with the product making it to our end of code targets, then the answer is a resounding NO!

A robust ATP sanitation verification program is only as good as the tools used to monitor the program.

What is ATP?

As a quick refresher, all organic matter (food products, skin cells, and microbes) has some level of adenosine triphosphate (ATP). ATP is the energy currency of all living cells, used to power the cell’s metabolic, cellular, and replication processes. A robust ATP sanitation verification program is looking for this molecule as it provides the nutrients for microbial survival if present and is an excellent indicator of sanitation effectiveness. It’s simple, the higher the number, the higher organic matter on the surface and the dirtier the surface.

Does this Sound Like Your ATP Sanitation Verification Program?

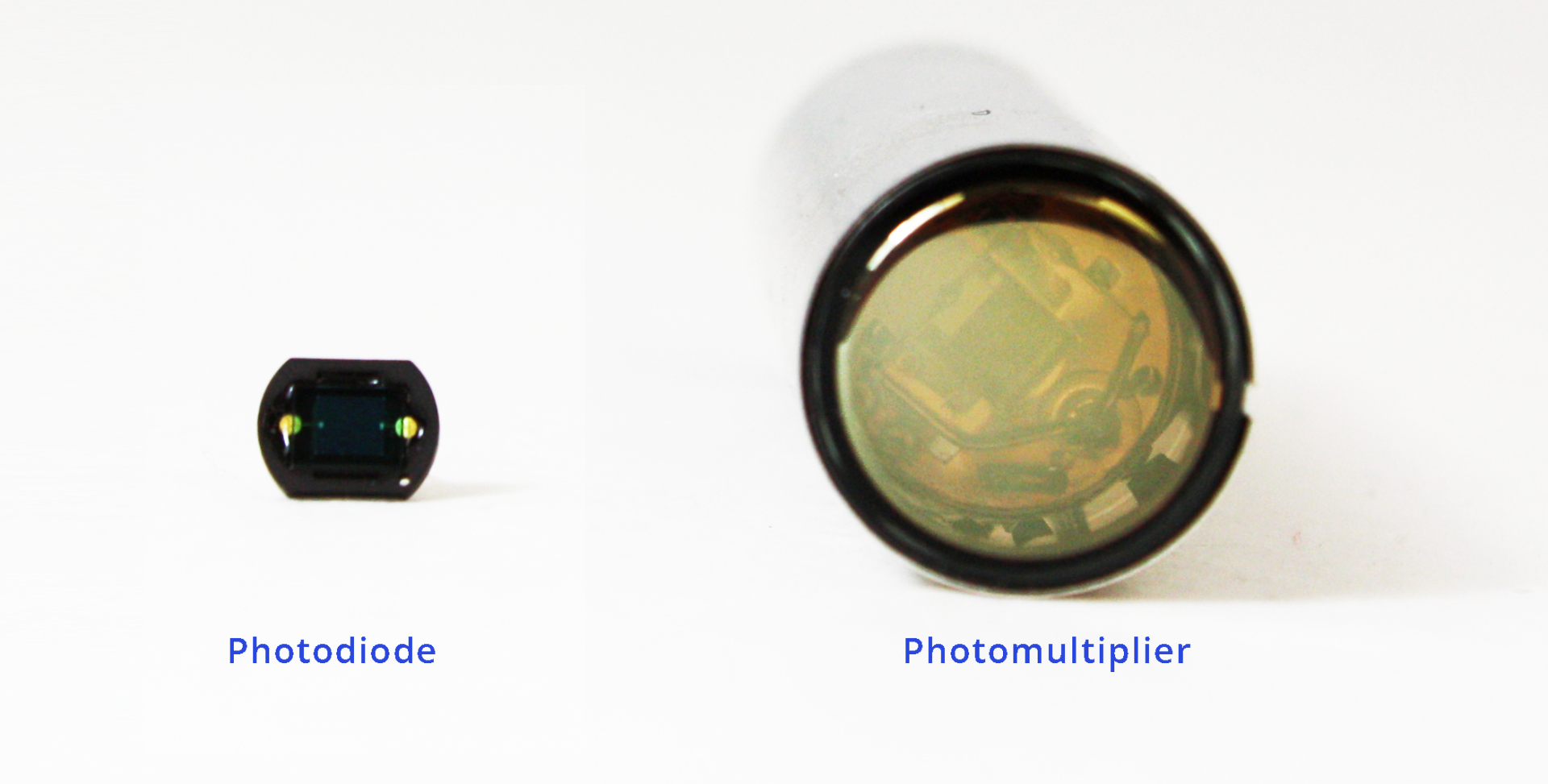

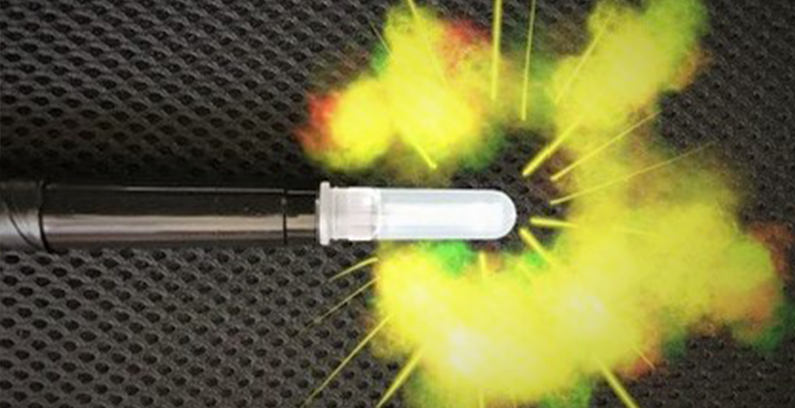

Although ATP RLU counts do not equate directly to microbial CFU (colony forming units), ATP used for sanitation verification helps identify unclean surfaces in 5 seconds. ATP testing initiates recleaning in real-time to help reduce the potential for microbial build-up on production lines that could impact food quality, spoilage, or worse, the risk of a recall due to ineffective sanitation practices. Further, the ATP needs to be interpreted by a luminometer that detects light. Different bacteria have varying cell wall thicknesses. When the swab chemistry cannot “break” microbial cell walls to release the ATP, coupled with a luminometer using a small photodiode, it cannot see the light to identify the surface as dirty. This causes you to get passing results providing a false sense of security that your sanitation verification program is effective.

Add Significant Value to Your Sanitation Verification Program

Choose an ATP test that utilizes a lysing agent in the swab to break the bacterial cell wall open, thus releasing the ATP to be analyzed. And use a luminometer with a light-magnifying photomultiplier to collect the actual RLU value. Selecting a quality luminometer and tests is the only way to understand if sanitation procedures are truly effective.

Implementing the next level of ATP analysis will bring your product to the next level of hygiene, mitigate the inherent risks of food safety, and protect your family and children from preventable hazards. It will add consumer confidence to your brand, which thus affects the bottom line in your favor.

Written By:

Brett Roeller

Territory Account Manager

Charm Sciences, Inc.

About Charm Sciences

Established in 1978 in Greater Boston, Charm Sciences helps protect consumers, manufacturers, and global brands from a variety of issues through the development of food safety, water quality, and environmental diagnostics tests and equipment. Selling directly and through its network of distributors, Charm’s products serve the dairy, feed and grain, food and beverage, water, healthcare, environmental, and industrial markets in more than 100 countries around the globe.